To use the wire gauge tool to find the suitable gauge size for a particular wire, simply remove the outer insulation and insert the wire conductor in the wire gauge slot one by one. It is a small circular shaped disc where different but common numbers are printed on it in accordance with the specific slots and holes. If you are on the job site and need to know the wire size gauge for the particular load, one of the quick solutions is to use the handy device known as wire gauge tool.

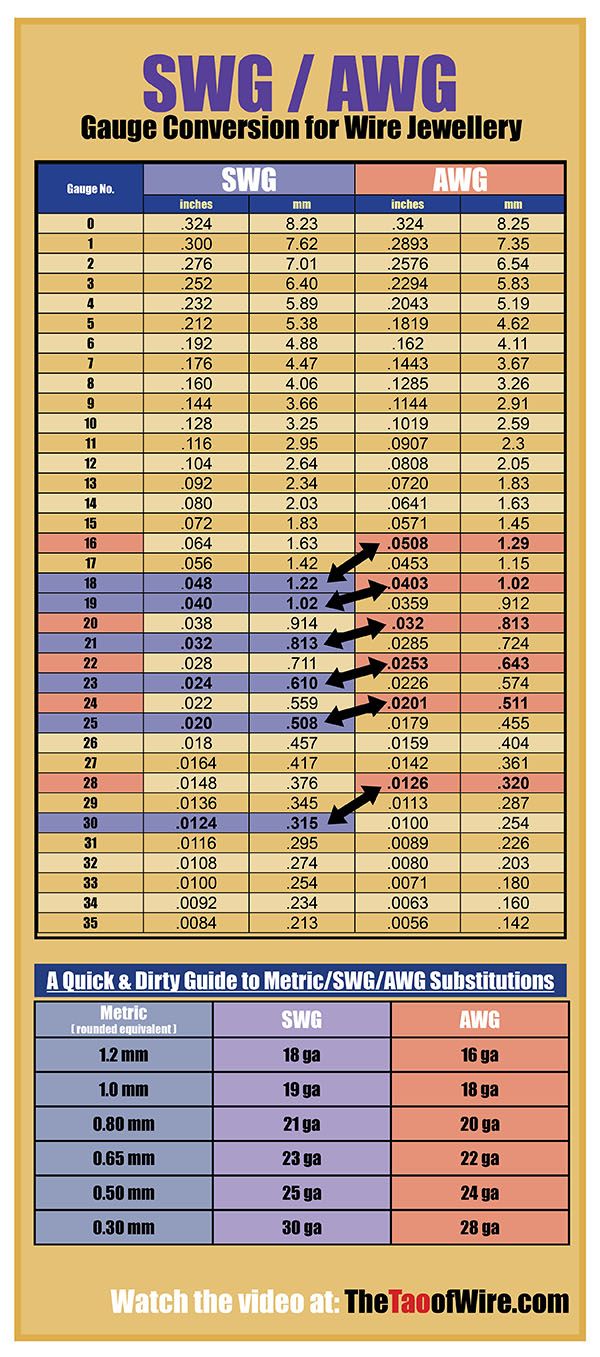

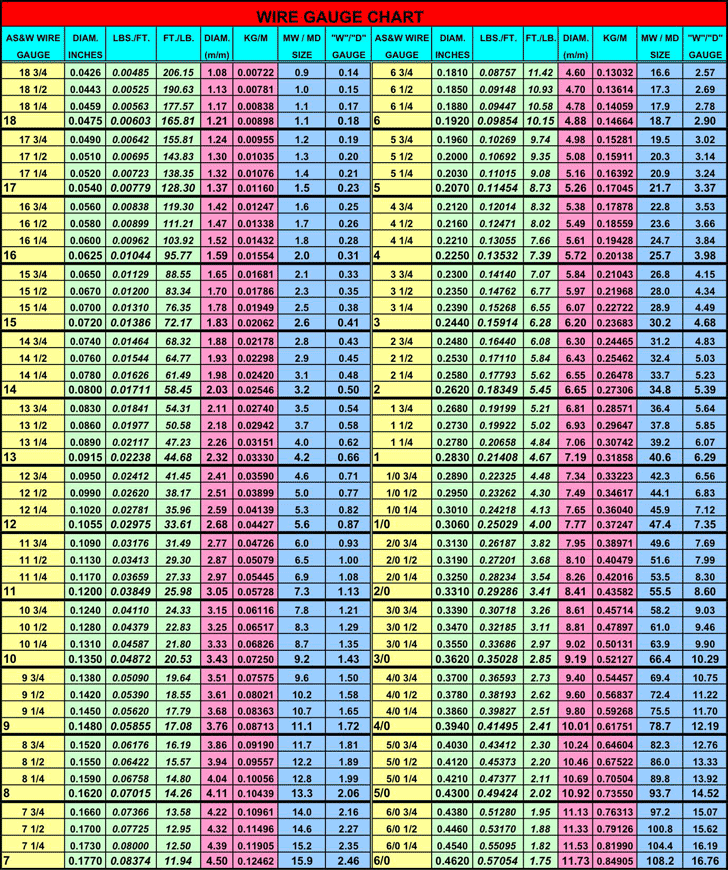

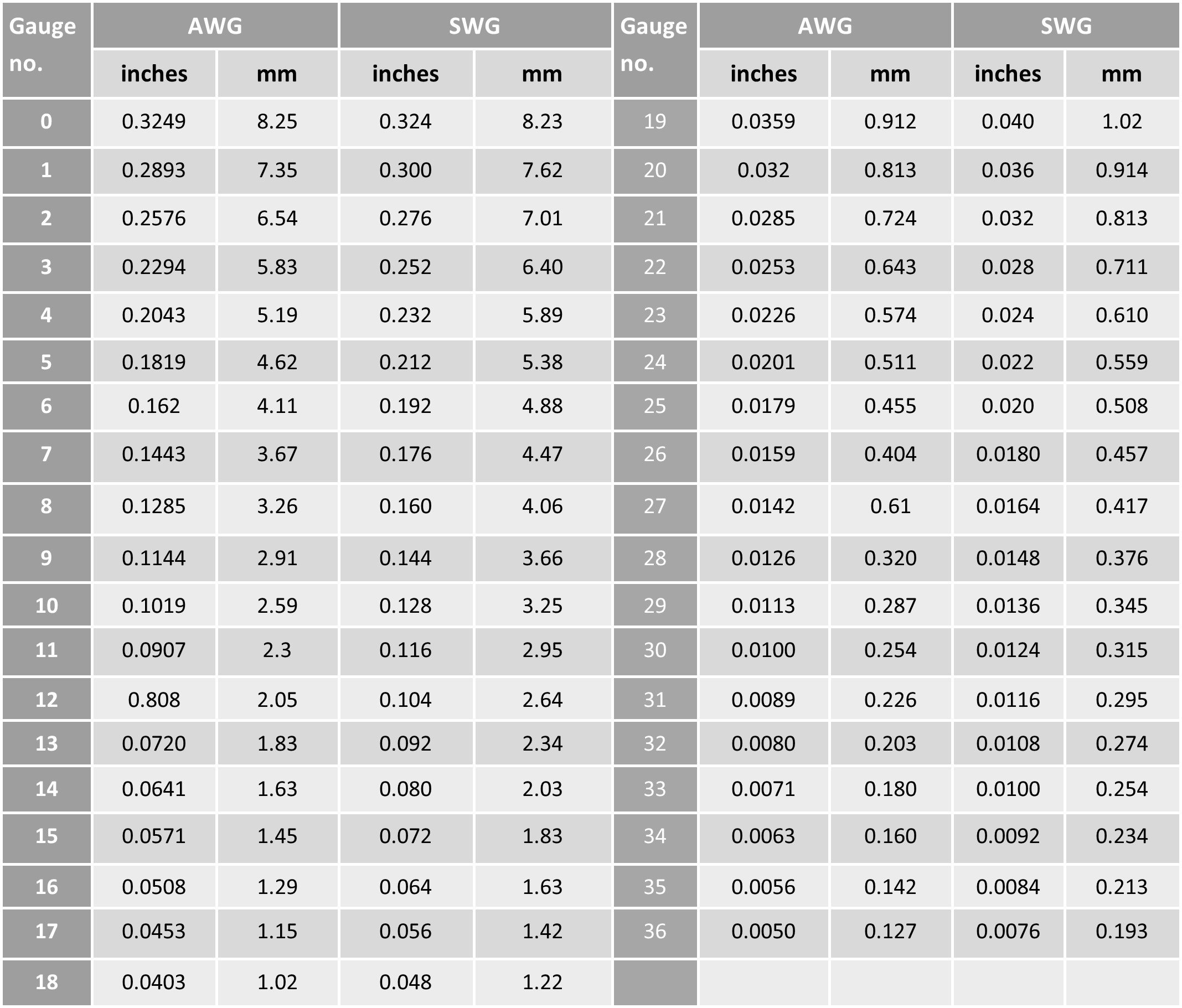

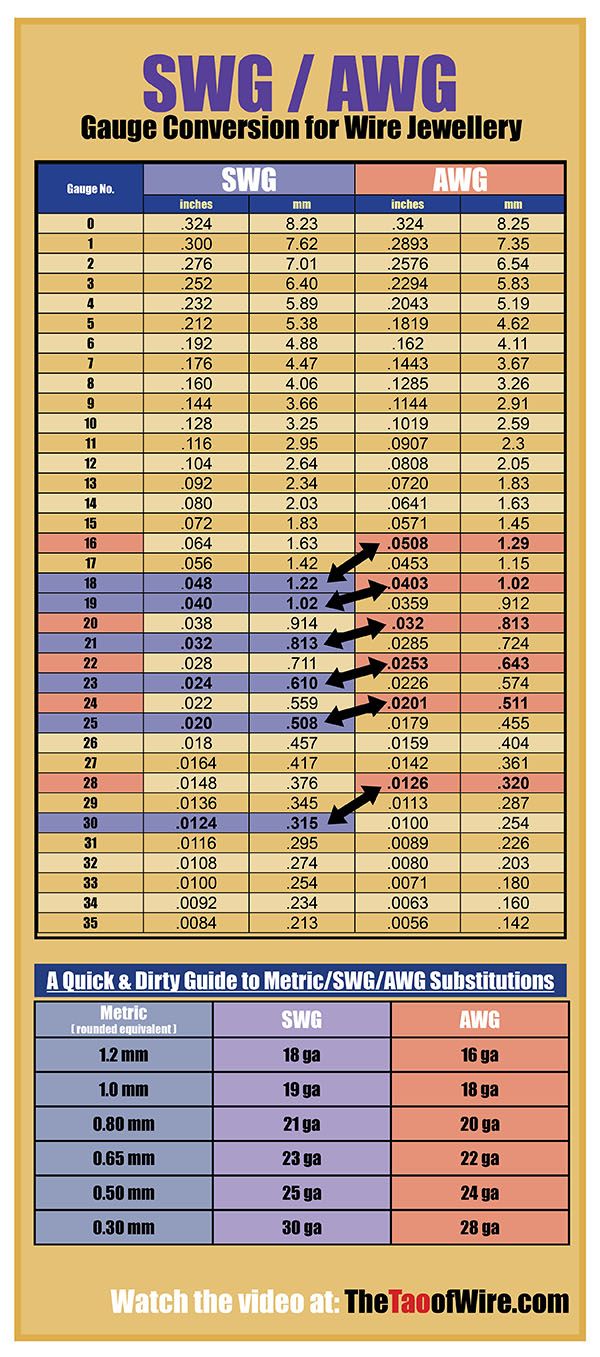

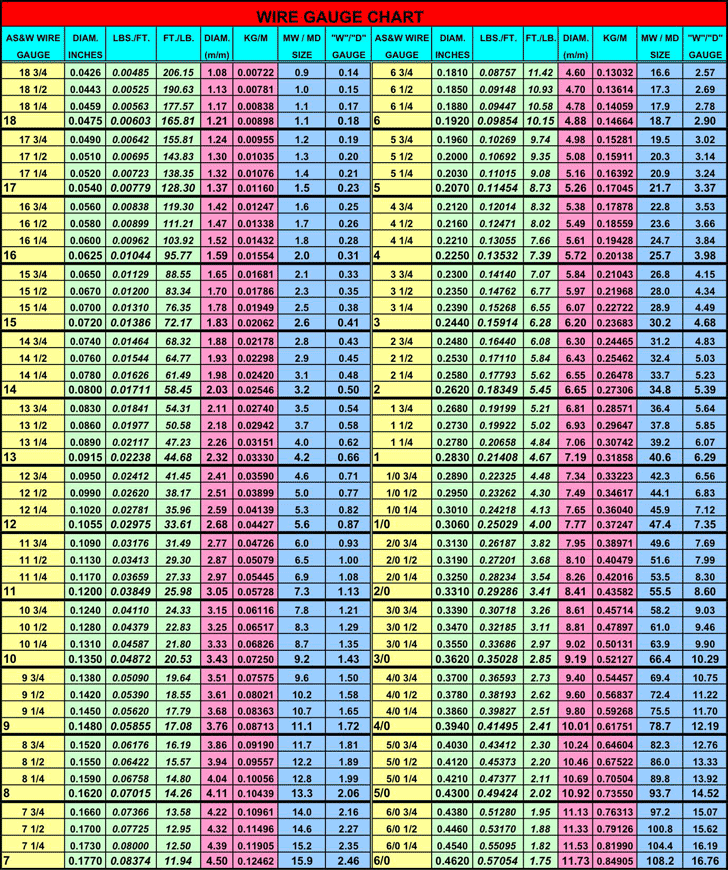

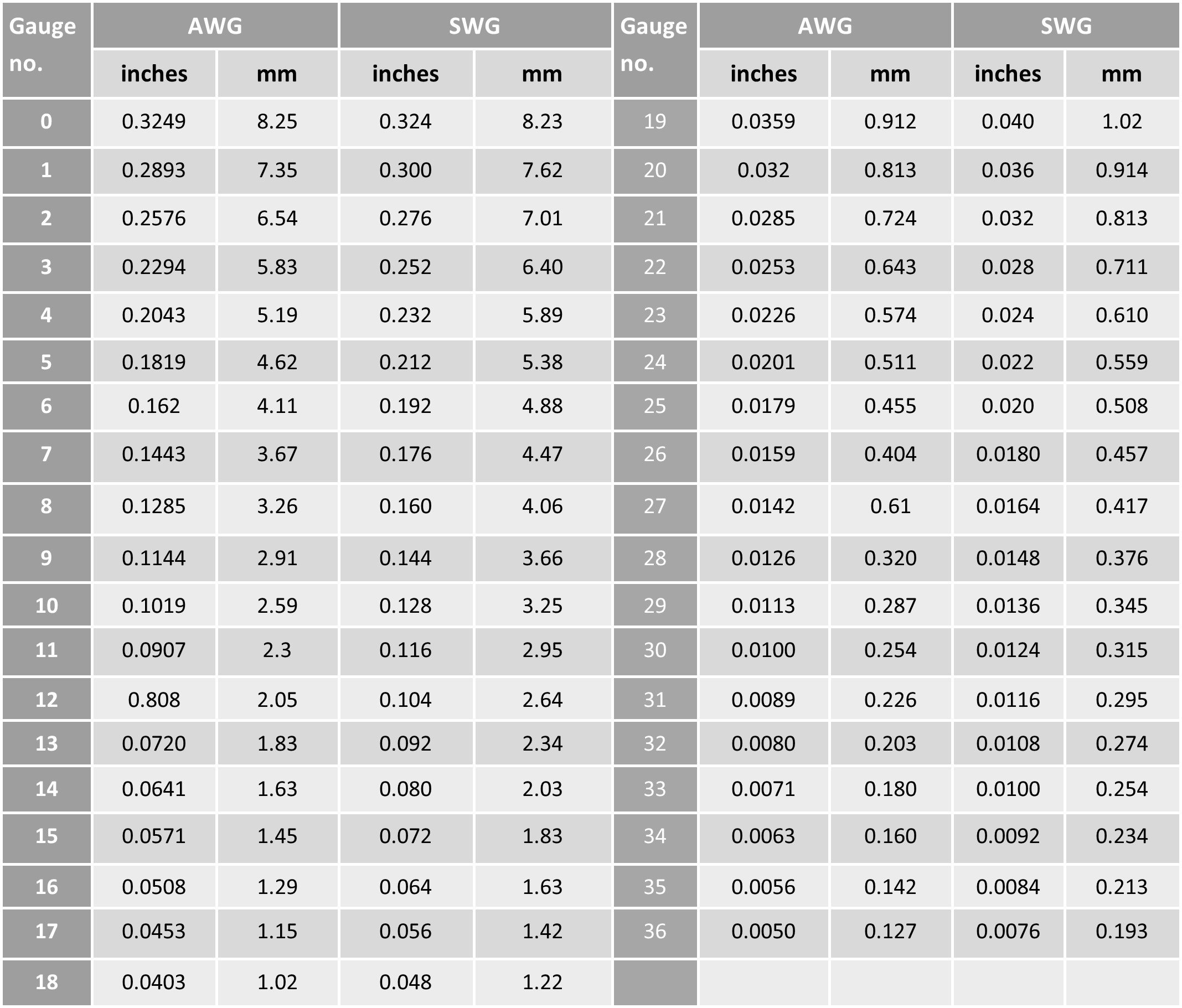

AWG/SWG to mm/mm 2, inch/inch 2 & kcmil Calculator & Conversion. Standard Wire Gauge “SWG” Calculator – SWG Size Chart & Table. American Wire Gauge “AWG” Calculator – AWG Size Chart & Table. Good to know: The American Wire Gauge (AWG) is also known as B and S Gauge (Brown & Sharpe Gauge). the higher the AWG size, the lower the ampacity and vise versa. In short, the ampacity is inversely proportional to the size of AWG integers (from 0000AWG to 40AWG) e.g. For example, the 14AWG size is a suitable wire for a 15Amp circuit breaker, whereas the 8AWG size is most appropriate for 40Amps of circuit breakers and load points. One thing should be noted about the AWG that the larger the integer, the smaller the thickness and diameter of wire. One of the most important roles of American Wire Gauge is to measure the current carrying capacity in Amps of wire (aka Wire Ampacity = The amount of maximum current that a conductor can carry continuously without exceeding its temperature rating. As lower gauge wires (such as AWG 4) are thicker, they can accommodate more electrons than higher gauge wires (such as AWG 40).The AWG is used to exactly measure the diameter of a particular conductor (such as solid, stranded, round and non-ferrous (alloys or metals that do not contain any appreciable amounts of iron) materials e.g. Current capacity is a measure of the amount of current a wire can carry safely. 2485Ω for 1000 feet, while AWG 40 wire has a resistance of 1079Ω for 1000 feet.) (e.g., At 25° C, AWG 4 wire has a resistance of. Given two wires of the same length, the thicker wire would have smaller resistance than the thinner wire. Longer wires provide greater resistance than shorter wires. A wire’s electrical resistance depends on its length and thickness. (e.g., AWG 4 wire requires 7.918 feet, while AWG 40 requires 34.364 feet.) Feet per pound refers to the number of feet of wire needed to reach one pound in weight. The wire’s cross-sectional area doubles every time it descends three levels (e.g., a six-gauge wire has double the cross-sectional surface area of a nine-gauge wire). The cross-sectional area of round wires can be calculated using the formula A= πr2, with r representing half of the diameter. The diameter doubles every time the gauge decreases by six levels (e.g., a three-gauge wire has double the diameter of a nine-gauge wire). For example, AWG 4 is 0.2043 inches in diameter, and AWG 40 is. Wire gauges range from low numbers to high numbers, with smaller numbers referring to smaller diameters and larger numbers representing larger diameters.

Given its gauge, industry professionals can determine the following about a particular wire:

The gauge of a wire imparts more than information about its thickness. Relationships Between Wire Gauge and Other Technical Specs

0 kommentar(er)

0 kommentar(er)